Revolutionizing Semiconductor Manufacturing: The Future of Wafer Handling Automation in Wafer Front End

In the ever-evolving technology sector, the semiconductor industry plays a key role in forming electronics as we know it. Not to mention, cutting-edge advancements are made possible through intricate processes that involve everything from minuscule microchips to massive wafer manufacturing. Here, in this post, we delve into the world of wafer handling automation, exploring its profound impact on the Wafer Front End, a critical stage in semiconductor production.

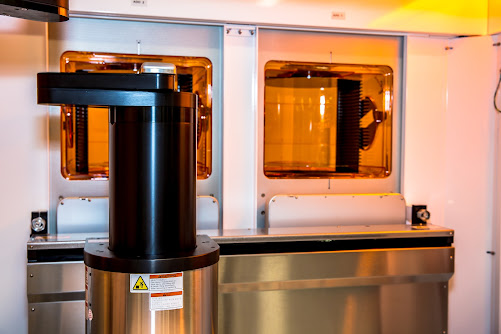

The Heart of Semiconductor Manufacturing

At the heart of semiconductor manufacturing lies the Wafer Front End, where silicon wafers are transformed into integrated circuits. This process is both intricate and sensitive, and it's here that we find the first intersection with wafer handling automation. Let's take a closer look at why this is a game-changer.

Precision and Efficiency

Wafer handling automation introduces a new level of precision and efficiency to the semiconductor manufacturing process. Unlike human operators, automation systems are not prone to fatigue or errors, ensuring every wafer is handled with the utmost care. The reduction in human intervention also minimizes the risk of contamination, one of the most significant concerns in wafer fabrication.

Seamless Workflow Integration

In modern semiconductor facilities, seamless workflow integration is paramount. Wafer handling automation systems are designed to seamlessly integrate with existing wafer front end manufacturing processes, optimizing the flow of wafers from one processing stage to the next. This integration not only enhances efficiency but also improves the overall quality of the semiconductor devices produced.

Safety and Reliability

The safety of both operators and the delicate wafers is a priority in semiconductor manufacturing. Wafer handling automation reduces the risk of accidents and minimizes the need for manual handling. Additionally, these systems are built with redundancy and fail-safe mechanisms to ensure the reliability of the entire production process.

Consistency and Quality Control

Consistency is a critical factor in the semiconductor industry. By automating the handling of wafers, manufacturers can maintain a high level of consistency in terms of wafer positioning, cleanliness, and overall quality. This consistency is vital in meeting the stringent specifications of modern wafer front end semiconductor devices.

Customization for Diverse Needs

Wafer front end semiconductor manufacturing is a diverse field with various products and applications. Wafer handling automation systems are designed with flexibility in mind, allowing manufacturers to customize the handling process to suit the specific needs of their production lines. This adaptability is crucial in a world where the demand for specialized semiconductor devices is rising.

Cost-Effective Solutions

The implementation of wafer handling automation systems is an investment that pays off in the long run. While the initial costs may be substantial, the long-term benefits in terms of reduced labor costs, increased productivity, and minimized wafer wastage make these systems a cost-effective solution for semiconductor manufacturers.

Industry Growth and Evolution

The semiconductor industry is in a perpetual state of growth and evolution, driven by consumer demand for smaller, faster, and more powerful devices. Wafer handling automation is at the forefront of this evolution, enabling wafer front end semiconductor manufacturers to keep up with the pace of innovation. As wafer sizes decrease and production volumes increase, automation becomes not just a choice but a necessity.

A Sustainable Approach

In a world increasingly focused on sustainability, wafer handling automation systems can contribute to a greener future. These systems are developed to minimize the usuage of energy and lower waste generation, aligning with the industry's push for more eco-friendly manufacturing practices.

Conclusion

In conclusion, wafer handling automation revolutionizes the Wafer Front End in semiconductor manufacturing. Its preciseness, efficiency, safety, and cost-effectiveness have become indispensable to the industry's growth and evolution. As the need for more miniature, more robust appliances persist to become greater in extent, wafer handling automation is poised to play a pivotal role. Clearly, the semiconductor industry's future is intricately linked to the future of wafer handling automation.

.jpg)

Comments

Post a Comment