Defects Associated with Silicon Wafer

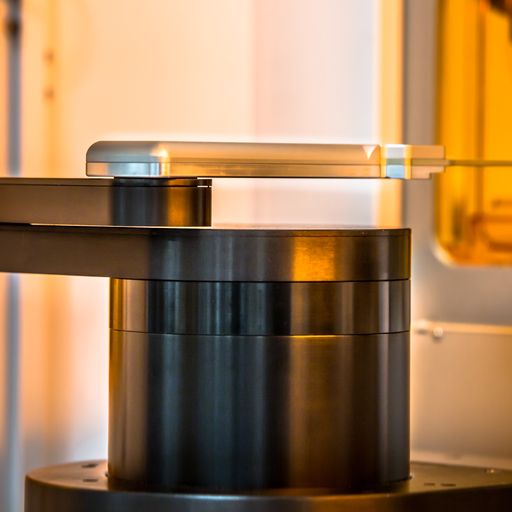

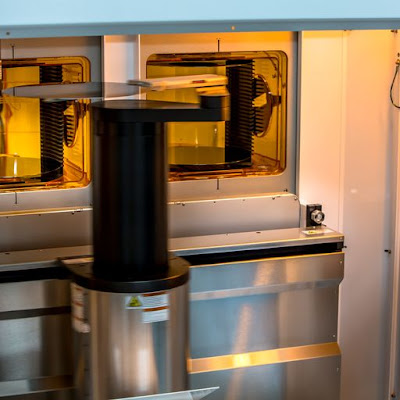

Are you in the semiconductor or manufacturing industry, where you must deal with wafers daily? Finding it challenging to handle thin-sized wafers? There is various thin wafer handling equipment available in the market to help you out with this issue. Many spin-coating applications need to be able to coat, develop, and rinse thinner and delicate substrates equally. There are many different types of substrates, but some of the more well-known ones are flexible polymer films, polyester, and metal foils. Safe handling of these delicate materials requires specially manufactured spin chucks and thin-wafer handling methods. Additionally, the through-silicon via (TSV) technique for 3-D wafer stacking is moving up on the priority list of the microelectronics sector. With this technology, the thickness of the substrate must be significantly reduced, and the handling requirements for each subsequent processing step become increasingly more complicated. Issues Associated with