Future of Semiconductor Manufacturing: How Wafer Handling Automation is Revolutionizing Production

.jpg)

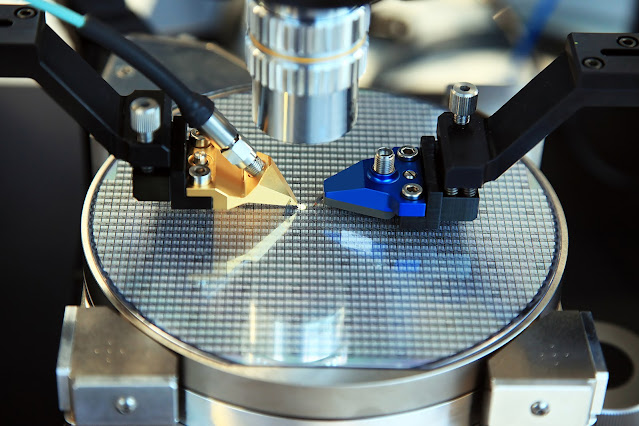

The semiconductor industry is the backbone of modern technology, powering everything from smartphones and laptops to advanced medical devices and autonomous vehicles. As the demand for smaller, faster, and more powerful chips continues to soar, the industry is constantly seeking ways to enhance efficiency, precision, and throughput in manufacturing. One technology that's playing a pivotal role in this evolution is wafer handling automation . Understanding Wafer Handling Automation At its core, wafer handling automation involves the use of robotic systems and sophisticated software to manage the movement, processing, and tracking of semiconductor wafers throughout the manufacturing process. Wafers, thin slices of semiconductor material, are the building blocks of integrated circuits (chips). Traditionally, wafer handling was a labor-intensive and error-prone process, but automation has revolutionized it. Benefits of Wafer Handling Automation Wafer handling automat...

.jpg)

.jpg)

.jpg)