Height, width, depth, and time are the four dimensions of the automation world. Motion control, the regulation of position, speed, and acceleration is necessary when the machinery must place an object in a specific location. More than most other fields, precision motion control is used in the fabrication of objects for specialized applications.

Previously impractical use cases suddenly become conceivable when digital information is converted into precise physical movements. Applications, including sophisticated robotics, the Internet of Things (IoT) and Industrial Internet of Things (IIOT), battery-operated medical devices, additive manufacturing, and prosthetics, all benefited from the introduction of Industry 4.0 as a result of this development. Each of these applications calls for extremely precise manufacturing machinery control. Therefore, more than just converting data into movement is needed for these applications to place parts accurately and accurately translate digital information into physical motion.

Precision Motion Control

Stepper motors are used in precision motion control to direct the position of the machine's active components. A stepper motor is used in open-loop systems to translate the electric control signal into the exact rotational position of the shaft. Engineers include a check feature to measure the location of the shaft for more excellent precision applications.

To enable variance correction, the measurement instrument transmits dimensional data back to the controller for comparison with the setpoint. Closed-loop communication refers to two-way communication. One of the most well-known uses for high-precision motion control is CNC milling, but other applications like desktop manufacturing and 3D printing also profit from tighter tolerances.

Pick-and-place machines, automated assembly lines, and inspection equipment that feeds data back to the controller are three further applications for high-precision motion control.

High-Precision Applications

Medical

Pumps and ophthalmic equipment, for example, require precise control at low speeds. Applications such as tissue analysis, blood centrifugation, and liquid handling offer chances for a low-speed, low-vibration precision solution.

Many technologies offer current loops that are almost perfectly sine waves to alleviate excessive vibration. The rounded curves reduce vibrations that would impair tolerances. Ineffective current conversion in the motor causes the component to heat up, fail the system, or initiate an automated shutoff.

Industrial

Product development for industrial applications is driven by productivity and throughput. Sophisticated diagnostics of many technologies and networked drives enable an intelligent factory as motion control advances.

By producing building blocks that system designers can utilize to construct the most effective, specific solution for their needs, the technology is strong enough to apply to standalone applications and networks.

Conclusion

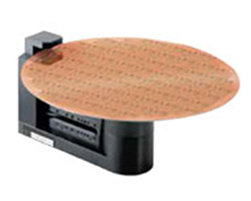

Two significant macro industries, medical and industrial automation, were changed by precision control. The key to both is precise motion control. It also reduces the tolerance of automatic movement significantly to increase precision while improving the performance of vibration, energy efficiency, noise, and smoothness of motion. If you need semiconductor front-end wafer handling robots for your company's needs, feel free to let us know about your requirement, and Kensington Labs will deliver a tailor-made solution to you.

Comments

Post a Comment