Everything You Need to Know About Semi-Conductor Vacuum System!

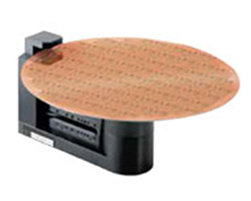

All semiconductor applications that need exact wafer handling automation depend on reliable vacuum performance. Wafer transportation needs to be carried out in pristine conditions. A semiconductor vacuum system's components must all be produced with productivity in mind and end-process yield. Many things we use daily are made using vacuum techniques such high precision cutting, die casting, coating, and shaping.

Stretching Our Understanding

Vacuum systems like those used in machining centers provide the low-pressure environments needed for advanced tool machining and testing. We have learned much about applications like accelerators and space chambers because of vacuum settings. Experiments with semiconductor systems broaden our understanding of scientific applications.

Adaptor Plates

In the course of manipulating workpieces inside the machine, expensive parts may deteriorate as a result of contact with debris. Both horizontal and vertical machining centers can cut heavily while moving quickly. This kind of agile production secures the workspace using interlocking doors and a semiconductor vacuum system.

In order to prevent wear, adaptor plates act as a crucial contact between a workpiece and the machine's components.

Shafts & Flanges

Shafts and flanges are frequently employed in semiconductor vacuum systems and have strict dependability, rigidity, and corrosion resistance requirements. Shafts are often composed of stainless steel, with exceptional oxidation and excellent corrosion resistance. Aluminum alloy flanges are strong and lightweight, maintaining corrosion resistance even when surface wear occurs.

Source Chamber

Low-pressure chambers must be sealed in order to operate at their best. Sealing rings of stainless steel ensure the chamber is airtight, particularly in machining centers where high-precision die casting and metal cutting are carried out.

Seals must be used to ensure that no unwelcome air enters the vacuum. Semiconductor systems depend on the source chamber's seal integrity which is flawlessly maintained. If you are exploring the best wafer automation provider, Kensington Laboratory must be your one-stop solution.

Bracket Supports

A semiconductor vacuum system must have sturdy steel, and aluminum alloy bracket supports if it lasts for a long time. The crucial parts of a machining system are held in place by bracket supports.

For instance, to ensure stability while work is being done, the vacuum chamber is securely attached using a stainless-steel bracket specially created for the purpose. The machine's motor is similarly secured by utilizing an aluminum alloy bracket.

Maintenance of Semi-Conductor Vacuum System

Every component significantly influences the smooth operation of a semiconductor vacuum system. It is essential to constantly inspect and maintain every vacuum system component to prevent expensive downtimes. Even one sealing ring failing might have catastrophic implications. Early leak detection is necessary to avoid the unintentional escape of harmful substances.

The more attention given to maintenance, especially in environments where safety is crucial, the better it will be for everyone.

Kensington automation solution is best for your product line if you are dealing in semiconductors or the manufacturing industry. We provide the best custom-made solution for you. You just need to let us know your requirements according to your need; we'll deliver a tailor-made solution.

Comments

Post a Comment