Rising Demand for Wafer Automation Solutions in 2022- Advanced Benefits

Due to the digital storm, the electronics industry is rapidly transforming. As the electronics and semiconductor manufacturing market is blooming, wafer handling robots have become a need of the hour. Wafer processing is the core of the electronics and semiconductor business.

Do you know that the wafer automation solution market is expected to rise by $65.29 Mn from 2021-2025 at a 5% CAGR?

Unbelievable, but these robots help in placing and moving wafers throughout numerous manufacturing processes in the semiconductor manufacturing market, thus making the process seamless. Robotic handling of the wafers ensures safe loading and unloading of applications and helps avoid human error and handling.

Use of Wafer Automation Solution Reduces Contamination

Do you believe that a tiny contamination particle becomes a big problem while handling wafers?

It is difficult to digest that a single microscopic particle can obstruct a conductor, affect diffusion, or distort a structure, but it is true. Eventually, it leads to the building of faulty products, minimized the product's lifespan, or the final product may come up with incorrect features. These tiny particles are either poised in gas or affixed to a surface.

The size of these contaminating particles varies from smaller than 10nm to more than 100µm.

Manual handling of the product can be the issue of particle contamination. The robotic parts are crafted with low particle counts.

There is no need for manual handling by the operator in a fully-automated system. Once the automated functioning has started, the programmed robots can help move wafers through all the processes without any operator intervention. Precision motion control is attained through the wafer automation solution. Along with reducing particle contamination, wafer handling robots improve the performance of semiconductor manufacturing facilities.

The high installation and maintenance cost of wafer handling robots act as a limitation in the market growth of the manufacturing industry. These robots demand continuous maintenance for smooth functioning that consumes a significant amount of the company's budget. Therefore, many manufacturing companies find it hard to deploy in their environment. It eventually leads to the lower overall growth of the market.

Impact of COVID-19 on Wafer Handling Robotic Industry

The global pandemic COVID-19 provoked the need for the implementation of containment measures. It was a dire need to break the lifecycle of the virus. During that period, the growth and expansion of many economic sectors like the travel and hospitality industry were stagnant. Most businesses including the wafer handling robotic industry have been badly impacted.

Types of Wafer Handling Robots

The wafer handling robots are broadly classified into two parts i.e., atmospheric robots and vacuum robots. The atmospheric system handling robots contributes to a major proportion of the market. On the other hand, vacuum system robots are also rising significantly.

Benefits of Kensington Laboratory Wafer Automation Solution

- The full range of benefits that Kensington laboratory's wafer automation solutions provide are:

- Higher yields

- More satisfactory throughput

- Exceptional repeatability

- Compatible with standard wafer carrier sizes and custom sizes

- Maximum output quality

- Less chemical usage

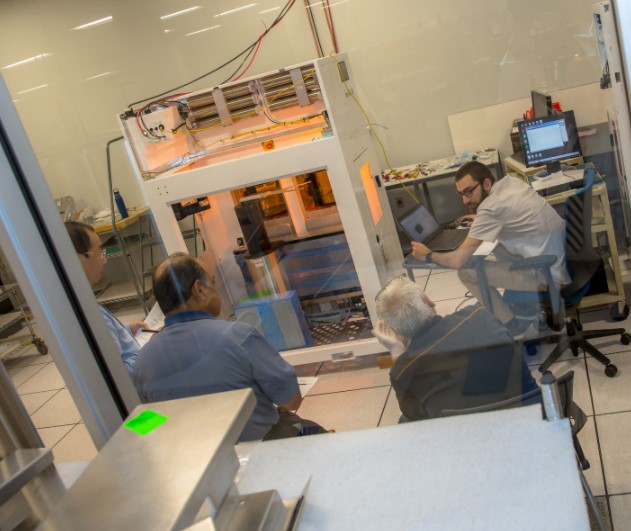

To get a trusted, reliable, and maintenance-free wafer handling solution, look no further than Kensington labs. The features, functionalities, and precision stage that they offer are incredible in the market. Moreover, you will get all these things at a very affordable price. They have a crew of fully-skilled and experienced professionals who work rigorously to offer the best-in-class products to clients. Above all, the environment used for crafting robots is ultra-clean. It is one of the reasons this brand is considered among the best laboratories that offer premium-quality products to the client.

We are giving the best wafer automation solution with excellent lifetime productivity.

If you have any queries related to Wafer Automation Solutions, feel free to contact Kensington Labs. Their experts are always a call away!

Comments

Post a Comment