Let's Combine the Semiconductor Expertise to Speed Up Your Production Process

With the advancement of technology, the semiconductor industry has evolved to the next level. There is a fall in production costs, thus rapidly enhancing the fabrication techniques, expanding markets, and driving new manufacturers' opportunities. As there is a disruptive shift in technology, the professionals encounter many challenges which demand forceful, cost-conscious responses. Today's semiconductor fabs labs require extensive automation & hands-off manufacturing capabilities. Get the Wafer Handling Automation Equipment to make your production process easy.

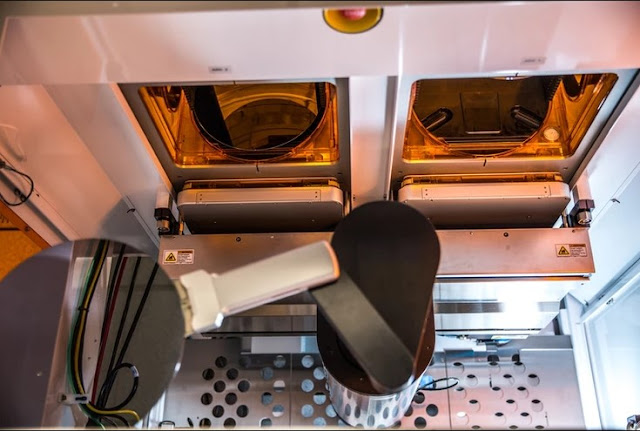

All the semiconductor industries are nowadays looking for high-performance specialized handling robots. They play a vital role in automating raw silicon wafers into integrated circuits. To get high-quality equipment, you must choose the leading supplier of integrated wafer handling robots.

Precise & Scalable Robots Rapidly Changing the Semiconductor Industry

The Wafer handling robots designed by the expertise must be accurate, high-speed semiconductors that enable manufacturers to automate silicon wafer transfer & logistics throughout the IC manufacturing process & are capable of meeting today's demanding throughput needs. The experts put all the efforts into designing the robots, which will reduce the error rates to an extent, boosts the quality & enhance throughput. With the help of Robotics' flexible automation solutions, the semiconductor equipment manufacturers may expect to retain their competitive edge over other competitors.

Have you Seen the Robots in the Cleanroom?

There are several things which need to be considered while working in the cleanroom. The main things involved are loading and unloading of process, measuring & test equipment's as there can be a need for the integrated handling within the machines. Many leading manufacturers are developing different robot-based solutions that help make manual intervention redundant.

Wafer Handling Equipment - Adaptable way to Automate the Process

In this modern world of automation, a need for the Wafer handling robots is on the rapid rise. Many manufacturers are designing robots that are capable of automating logistically complex processes which previously needed a high level of manual energy. There are many types of Wafer handling robots that are used to handle wafers. It includes transferring between several cassette types, filling with test or dummy wafers, sorting, wafer identification, and notch-alignment of wafers.

Handling of Additional Materials in Semiconductor Labs Becomes Easier

There are many materials or equipment used in the semiconductor industries which need special attention. Many companies nowadays work on making the whole manufacturing process automated in order to reduce the cost of manufacturing and speed up the process of production. Thus, there is a great need to handle the additional materials in Semiconductor Labs using highly automated tools.

We, at Kensington labs, consist of a highly experienced team of engineers, electronics technicians & software specialists who are working dedicatedly to develop & design Wafer handling robots & Wafer front end tools by using the latest technology. The robot solutions & automation systems manufactured by our experts are made from high-quality materials & products. Take advantage of our talented professionals and contact us! We will be delighted to meet your exact needs.

Comments

Post a Comment