A Brief Introduction to Wafer Handling Automation & Stage Repair

Wafer Handling automation is used to curb the silicon wafers from dust elements or small microns, which contributes to blocking the structure and stops the whole performance of the electronic devices. Therefore, just because of the advancements in the tools and technologies, it is likely for the semiconductor companies to propose the wafer handler automation in order to make improvisations in the front end and back end processes. One must know that the wafer handling equipment won’t need any meters or weight machine to compute the chemical proportion. It’s already been working on the software that analyzes the number of gases or chemicals required in a single chip or to make in operation a specific process.

What can we expect from water handling automation?

- Appropriately chemical distribution

- No more Meters needed

- High quality

- Budget-friendly option

What makes the wafer handling effective?

- Low energy consumption

- 360-degree rotation

- Ergonomic Design

- Easy loading and filling

- Personalized controls

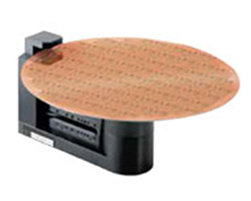

The grip automation system provides around 300mm FOUP of secured wafer handling, where the robots are operated with the optical sensing device to check the functionality as well as the environment. It is also easy to detect whether the wafers are placed at the appropriate location and, if not, where it should be.

If you are checking for the high rigidity linear subsystems, proportional servo drives, no backlash, or to resolve the problems in the machines, you must contemplate the wafer handling automation to practice the easy operations practically. So, you can check out the Kensington Labs that provides the personalized form motion controls, load ports, robotics as well as the precision levels in the modest range. The contemporary functionalities of wafer handling equipment, stage repair are the one-stop solutions to build up the performances of the semiconductor.

The stage repair services are the most powerful automatic motion controller products that can get the benefits from the life of robots without any struggle. Now, when it is about lowering the optimized capital investment and its obsoleteness then, these devices concerns about the heat and noise. You will find several stage repair systems in the market, but the Gantry precision control and the contract manufacturing equipment are the most commonly used ones. It also provides personalized solutions and carries a good range of speed.

What benefits can you extract from Stage Repairs?

Varyingly from the commercial to the technical aspects, everything is entirely gained by the stage and repair contract manufacturing services. It just defends the inventory cost if the product is bought from a reliable manufacturer. It can conclude the velocity and the travel range, such as the needs and carries out the easy breezy operations rather than generating backlash inking.

Don’t delay to check out Kensington Laboratories that provides the authentic products of precision handling robots to numbers of stage repair programs at a modest rate.

Nice blog! Keep sharing these types of blogs. For semiconductor wafer handling robots in USA, you can contact with Mitsubishi Electric Automation, Inc.

ReplyDelete