How Wafer Automation Helps Overcoming Productivity Challenges?

The complexity in the outsourced assembly and test (OSAT) the industry is blowing up owing to higher functionality demand, longer battery

life, and thinner forms in handheld devices. OSAT factories are readily using

complex packaging technologies for blurring the line between wafer packaging

and wafer processing. Through Wafer Automation we are able to meet the challenges of various wafer-level

architectures, like modern wafer fabrication.

The traditional packaging methods are no longer relevant; wafer automation has taken up the

transition. The fabrication life cycles, characteristics, and activities have

to be carefully learned before deploying in the OSAT environment. In this

competitive wafer-level packaging (WLP) era, it is crucial to have higher-level

manufacturing capabilities and engineering resources.

Comparison

Traditional OSAT production is relatively low-margin, and

all the packaging services were in support of wafer requirements. The advanced

packaging applications have relatively high margins and are growing much faster

than the semiconductor industry. The OSAT companies are overcoming the

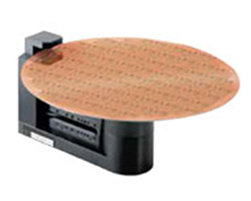

competitive and technological challenges using Kensington wafer automation to reduce waste and errors, and get higher levels

of output. The various automation strategies increase responsiveness and

flexibility leading to more efficiency.

What Are The Automation Strategies For WLP?

WLP factories face challenges to deliver multiple products

of various sizes at acceptable yield levels that manage varying levels of

complexity and handles time commitments with the latest methodologies. They

closely resemble wafer fabrication in structure, performance, and operations.

The WLP factories need tools for photolithography, sputter, CMP, dielectric

deposition, plating, cleaning, inspection, measurement, and testing. Each

equipment to be used should be single-wafer, so that batch operations meet the

production requirements. The production tools and automated material handling

systems should be 300mm for operations. The monitoring and controlling of such

complex production operations are beyond the OSAT companies did in the past.

Comments

Post a Comment