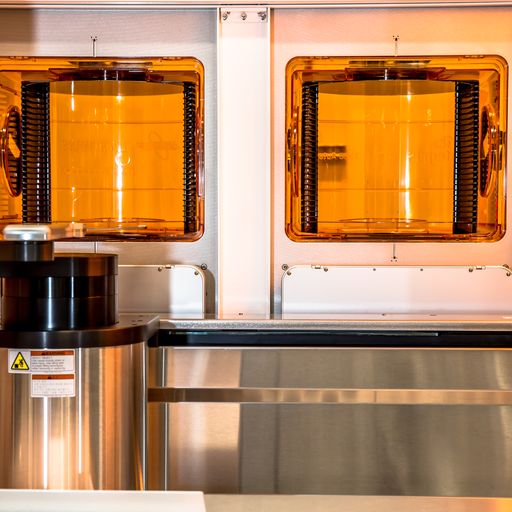

Find the Defects on a Wafer with Advanced Semiconductor Wafer Defect Inspection System

The semiconductor sector is mainly engaging in designing as well as fabrication of semiconductors . It has been analyzed that the automation sector is in great demand for the entire electronics manufacturing industry. There are many professionals who provide the best wafer stage solutions . So, you must rely on the best experts that will meet your exact demands. When it comes to precision linear & rotary positioning stages, the semiconductor wafer inspection sector needs high precision. Metrology as well as inspection are considered the two essential terms used for the management of the semiconductor manufacturing process. There are approx. hundreds of steps involved in the overall manufacturing process of semiconductor wafers which, of course, takes a lot of time. If any defects occur early in the manufacturing process, all the work undertaken to perform the steps will be wasted. That is why metrology & inspection processes must be establishe...